Shanghai Aludream Building Material Co.,Ltd

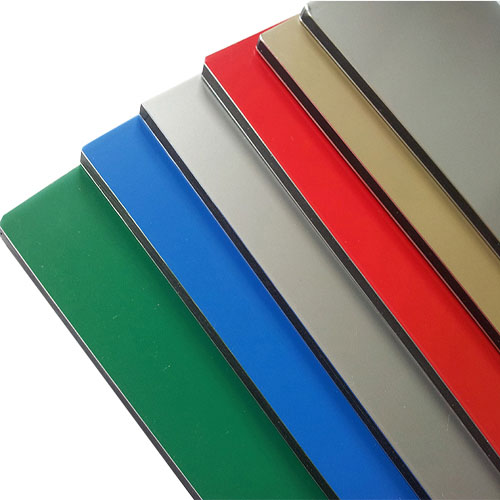

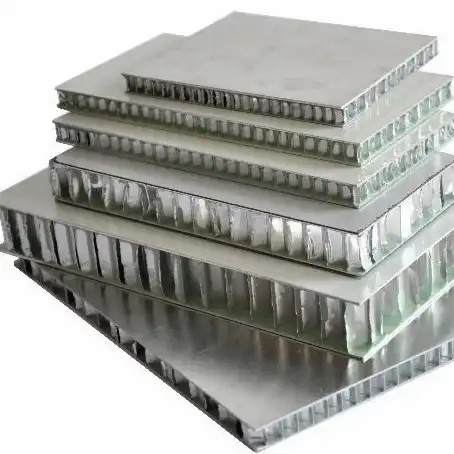

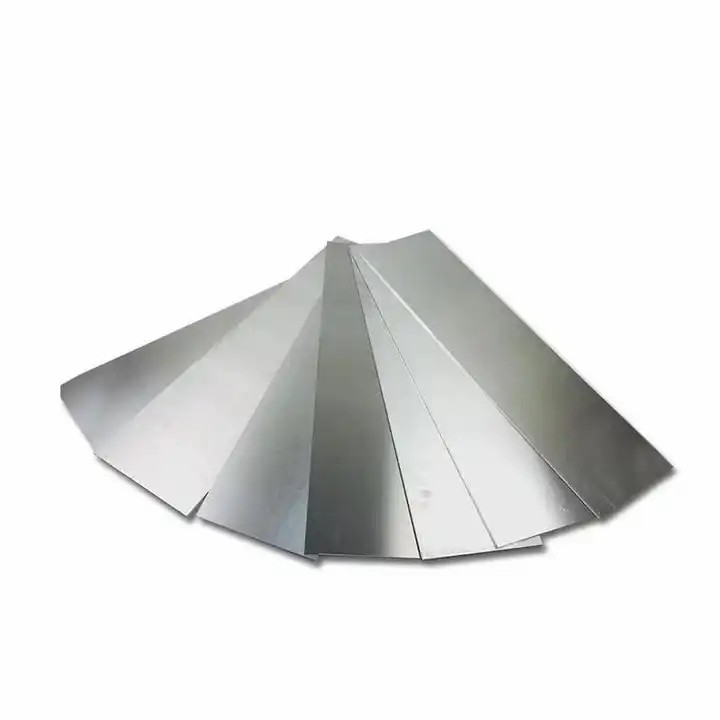

Shanghai Aludream Building Material Co., Ltd is a professional aluminum composite panel manufacturer in China, The company mainly produces Aluminum Composite Panel China, Color Veined Aluminum Composite Panels, Fireproof Aluminum Composite Panels, Advertisement and Signboard Aluminum Composite Panels, PVDF Aluminum Solid Panels, Honeycomb Aluminum Sheets, Aluminum Ceilings and Roof, Metallic finish insulation boards,aluminum coil, etc.

Our factory has 10 production lines, 3 coating lines. The annual production capacity is over 10, 000, 000 square meters. Since the company was founded, the enterprise has been certified by ISO9001:2008 International Quality Management System, ISO14001:2004 International Environment Management System, OHSAS18001:2001 Occupation Health Safety Management System and the products quality get approvals of CTC and CE, The products have been approved by SGS Fireproof Grade B1, and excellently approved by the sampling inspections by China Building Material Testing Center and China Quality Supervision & Testing Center.

3 + Coating Lines

10 + Production Lines

18,000,000 + Square Meters Annual Productivity

Exhibitions and Customers

![[list:title]](/template/default/images/index/acp.jpg)

![[list:title]](/template/default/images/index/honey.jpg)

![[list:title]](/template/default/images/index/arc.jpg)

![[list:title]](/template/default/images/index/pvc.jpg)